WSD Load Break Switch

I. Overview

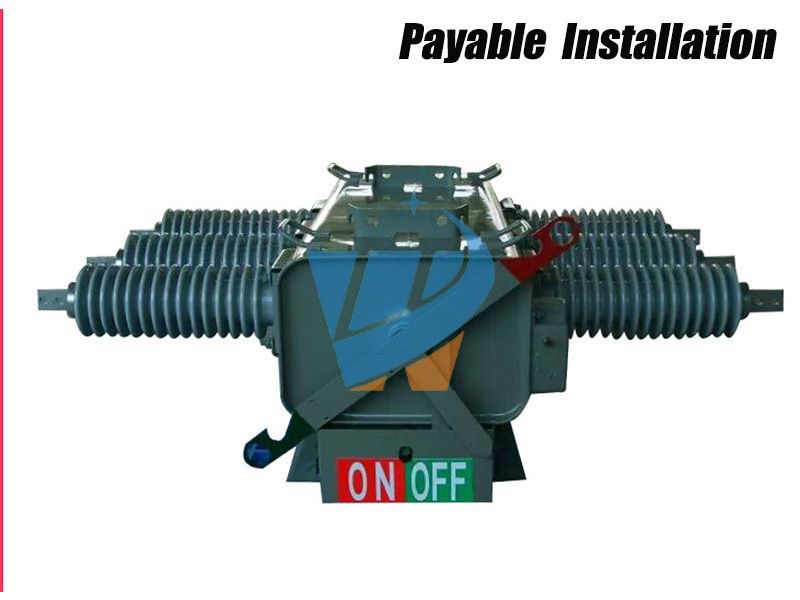

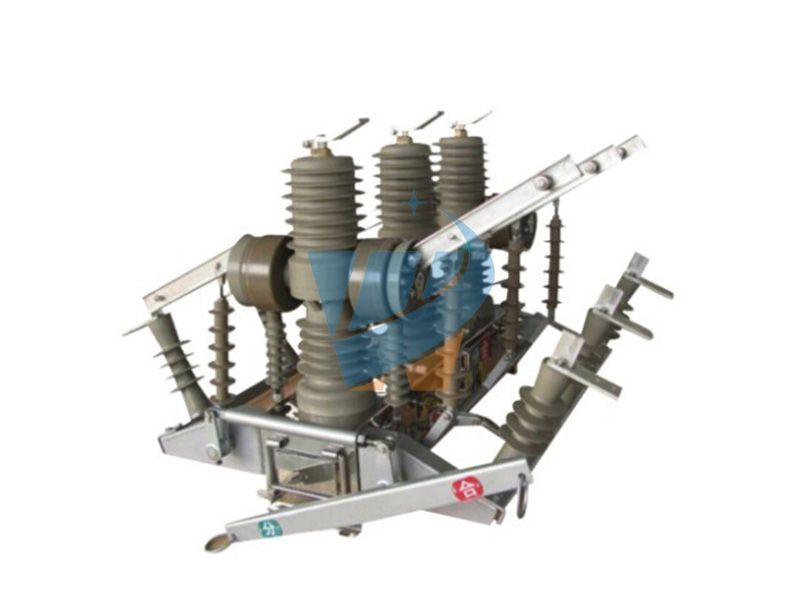

WSD-FLW34-24 SF6 load switch is suitable for outdoor three-phase AC distribution system with rated voltage of 24 kV and rated frequency of 50/60 HZ. It can be used for on-off and off-load currents and short-circuit currents. The products are suitable for substation, industrial and mining enterprises, protection and control of farm network, automatic distribution network of farm network and frequent operation places.

WSD-FLW34-24 SF6 load switch is used for operation control switch of overhead line distribution system. There are many types. It has many outstanding advantages, such as no oil, simple mechanism, reliable performance and no maintenance, and has been widely used so far. This product combines with FDR type fault detector or RTU remote control terminal device to form a very simple distribution automation system, which can realize automatic fault location of overhead lines and automatic isolation of fault sections.

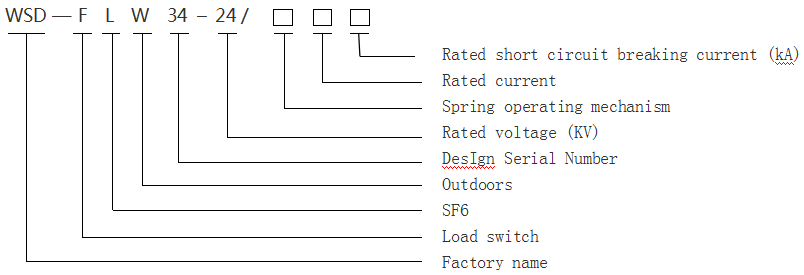

∥. Type Meaning

Ⅲ.Characteristics

1. SF6 gas insulation, non-toxic, non-flammable, with excellent arc extinguishing characteristics.

2. In addition to standard ceramic bushing, the bushing can be made of silicone rubber/epoxy resin and other materials.

3. Visible disconnection/closure (green disconnection; red closure).

4. Use the spring energy storage operation mechanism to ensure quick closing and opening operation (less than 100 milliseconds).

5. Remote control can be achieved: with the electronic controller, it can be operated locally or the main console can be operated by FTU interface.

IV. Technological Parameters

| No | Name | Unit | Data | |||

| 1 | Rated voltage | kV | 12 | 24 | ||

| 2 | Rated Frequency | Hz | 50/60 | 50/60 | ||

| 3 | Rated insulation level(SF6 gas filled 0.07 Mpa/ At 20 C) | Lightning Impulse Voltage Resistance | Interphase, relative | kV | 75 | 125 |

| Fracture | 85 | 145 | ||||

| Power Frequency Voltage Withstand1min | Interphase, relative | kV | 42 | 64 | ||

| Fracture | 50 | 79 | ||||

| 4 | Insulation Level under Zero Meter Voltage | Power Frequency Voltage Withstand 1min | kV | 30 | ||

| Inverse phase withstand voltage 1min | 30 | |||||

| Maximum Phase Voltage 5min | 9 | |||||

| 5 | Rated current | A | 630 | 630 | ||

| 6 | Rated interruption load current(0.07Mpa /At 20℃) | A | 630 | 630 | ||

| 7 | Open-off Current under Zero Meter Pressure | A | 630 | 630 | ||

| 8 | Peak Tolerance Current | kA | 50 | 50 | ||

| 9 | Rated short-time closing current | kA | 50 | 50 | ||

| 11 | Icw | KA/s | 20/4 | 20/4 | ||

| 12 | Rated Cable Charging Open-Out Current | A | 25 | 25 | ||

| 13 | Rated line charging switching-on current | A | 16 | 16 | ||

| 14 | Rated closed-loop switching-off current | A | 630 | 630 | ||

| 15 | Excitation current | A | 21 | 21 | ||

| 16 | Rated Current Interruption Number | Time | ≥400 | ≥400 | ||

| 17 | Rated working pressure | MPa | 0.07 | 0.07 | ||

| 18 | Resistance of each phase main circuit | μΩ | ≤150 | ≤150 | ||

| 19 | Relative Gas Leakage Rate | year | ≤1% | ≤1% | ||

| 20 | Moisture Content of SF6 Gas | Out-of-factory handover value | ppm | ≤150 | ≤150 | |

| Switch Operating Value | ppm | ≤300 | ≤300 | |||

| 21 | Mechanical stability operation | Time | 6000 | 6000 | ||

| 22 | Rated operating voltage and rated auxiliary circuit voltage | V | DC 220/110/48/24 | DC 220/110/48/24 | ||

| AC 220/110 | AC 220/110 | |||||

| 23 | Weight | Type M(Manual operating mechanism) | kg | 115 | 125 | |

| Type A(Electric operating mechanism) | 135 | 145 | ||||

| 24 | Protection Level of Mechanism Box and Controller | IP54 | ||||

V. Conditions of Use

1. Ambient air temperature: upper limit + 50 and lower limit - 40 C.

2. Relative humidity: 100%

3. The altitude does not exceed 1000m; 2000m; 3500m. (According to the user's request when ordering. No requirement for conventional 1000m is proposed.)

4. The wind pressure should not exceed 700 PA (equivalent to 34 m/s).

5. Earthquake intensity: 8 degrees.

6. Installation site: No fire, explosion, chemical corrosion and frequent violent vibration.

7. Contamination Grades: Classes III and IV

about load switch

Brief introduction of load switch

The load switch is generally equipped with a simple arc extinguishing device, its structure is not only not complicated, but rather simple. The picture shows a kind of pressure type

The working process of the high-pressure load switch is: when opening, the main shaft rotates clockwise under the action of the opening spring,-the piston is moved upward by the crank slider mechanism to compress the gas; the other-the two sets of four The transmission system composed of the rod mechanism makes the main knife open first, and then pushes the arc extinguishing knife to open the arc contact, and the compressed air in the cylinder blows out the arc through the nozzle.

According to the voltage used, it can be divided into high-voltage load switches and low-voltage load switches.

High-load switches

1. Solid gas-generating high-voltage load switch: use the energy of the breaking arc to make the gas-generating material of the arc chamber produce gas to blow out

The arc has a relatively simple structure and is suitable for products of 35 kV and below.

2. Compressed high-pressure load switch: The compressed air of the piston is used to blow out the arc during the breaking process, and its structure is relatively simple and applicable

For products at 35 kV and below.

3. Compressed air type high-voltage load switch: Use compressed air to blow out the arc, which can interrupt a large current, and its structure is more complex

Miscellaneous, suitable for products of 60 kV and above.

4. SP6 high-voltage load switch: using SF6 gas to extinguish the arc, its breaking current is large, and the breaking capacitor current performance is good, but the structure is relatively

For complexity, it is suitable for products of 35 kV and above.

5. Oil-immersed high-voltage load switch: Use the energy of the arc to decompose and vaporize the oil around the arc and cool it to extinguish the arc. The structure is relatively simple, but the weight is large, suitable for outdoor products of 35 kV and below.

6. Vacuum high-voltage load switch: the use of vacuum medium to extinguish the arc, long electrical life, relatively high price, suitable for 220 kV and

The following products.

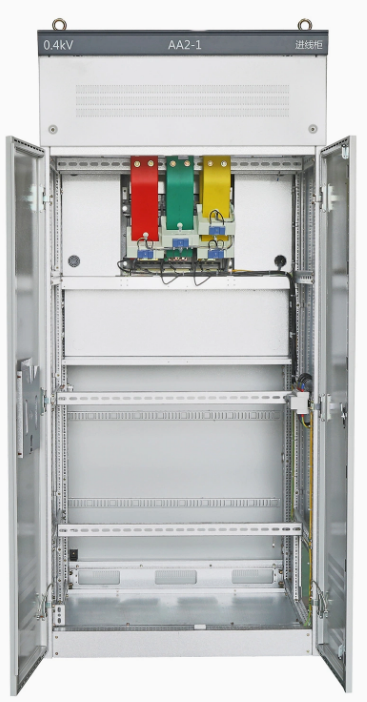

Low-voltage load switches

low-voltage load switches, also known as switch fuse groups. Suitable for AC power frequency circuit, infrequently by manual

On-off load circuit; can also be used for line overload and short circuit protection. The on-off circuit is completed by the contact knife, and the overload and short-circuit protection are completed by the fuse. The rubber-covered knife switches and iron-shell switches used before the 1970s are all low-voltage load switches. The opening and closing speed of the contact of the small-capacity low-voltage load switch is related to the operating speed of the handle. The operating mechanism of the low-voltage load switch with large capacity adopts the spring energy storage action principle. The opening and closing speed has nothing to do with the speed of the handle operation. The structure is relatively simple and is equipped with a reliable mechanical interlocking device. The lid cannot be opened after closing, which can guarantee the work safety.

The role of the load switch

The load switch refers to the electricity that can be closed, loaded, and broken under normal conditions in the power distribution system (which may also include the specified overload factor)

It is a switching device with special arc extinguishing contact, arc extinguishing device and spring breaking device. With the continuous development of science and technology, the types and quality of load switches have increased and improved. The more popular ones are vacuum load switches, gas-generating load switches and compressed-type load switches, which are one of the most critical equipment in the distribution network. From the structure _ point of view, the load switch is similar to the isolating switch (there are visible disconnect points in the off state), but it can be used to open

Closed circuit is similar to circuit breaker. However, the circuit breaker can control any circuit, and the load switch can only open and close the load current, or break the overload current, so it is only used to cut off and turn on the circuit under normal conditions, but not to open the short circuit fault current. However, its structure is required to pass the short-circuit fault current without damage. Because the arc extinguishing device and contacts of the load switch are designed to cut off and switch on the load current, in most cases, the load switch should be used in conjunction with the high-voltage fuse, which is responsible for cutting short-circuit fault current. The frequency and operating life of load switches are often higher than circuit breakers.

The advantage of the load switch is that it has large breaking capacity, safe and reliable, long life, frequent operation, and low maintenance. It is mostly used for 10

For distribution lines below 1000 volts, the arc-extinguishing methods include compressed air (FN12-12 load switch can be inverted), sulfur hexafluoride

SF6 (FLN36-12 load switch) and vacuum arc extinguisher (FZN21-12 formal installation, FZN25-12 side mounted vacuum load switch) and so on. .

The structure of the load switch is similar to the isolating switch, except that a simple arc extinguishing device is added. It also has an obvious breaking point, has a certain breaking capacity, and can be operated with load, but it can not directly cut off the short-circuit current. If necessary, it must be realized by the high-voltage fuse connected in series.

Working principle of load switch

The load switch is an electrical appliance with a function between a high-voltage circuit breaker and a high-voltage disconnector.

The circuit breakers are used in series; they are used to control power transformers. The high-voltage load switch has a simple arc extinguishing device, because it can turn on and off the constant load current and overload current. But it can not cut off the short-circuit current, so it is generally used in series with high-voltage fuses, with the help of fuses for short-circuit protection.

The working principle is as follows:

The working principle of high voltage load switch is similar to circuit breaker. -Generally equipped with a simple arc extinguishing device, but its structure is relatively simple. Fig

It is a kind of pneumatic high-pressure load switch, and its working process is: when opening, under the action of opening spring, the main shaft rotates clockwise,

-On the one hand, the piston is moved upward by the crank slider mechanism to compress the gas; on the other hand,-the main brake knife is opened first by the transmission system composed of two sets of four-bar linkage mechanisms, and then the arc extinguishing brake knife is pushed to open the arc contact , The compressed air in the cylinder blows out the arc through the nozzle.

When closing, the main knife and the arc extinguishing knife rotate clockwise at the same time through the main shaft and the transmission system, and the arc contact closes first; the main shaft

Continue to rotate, so that the main contact is then closed. During the closing process, the opening spring stores energy at the same time. Because the load switch cannot interrupt the short-circuit current, it is often used in combination with a current-limiting high-voltage fuse. The current-limiting function of the current-limiting fuse not only completes the task of breaking the circuit, but also significantly reduces the heat caused by the short-circuit current. And the role of electric power.

Therefore, the load switch is a switching appliance between the circuit breaker and the isolating switch, has a simple arc extinguishing device, can cut

Break the rated load current and a certain overload current, but can not cut off the short-circuit current.

Brief introduction of load switch

The load switch is generally equipped with a simple arc extinguishing device, its structure is not only not complicated, but rather simple. The picture shows a compression type

The working process of the high-pressure load switch is: when opening, the main shaft rotates clockwise under the action of the opening spring,-the piston is moved upward by the crank slider mechanism to compress the gas; the other-the two sets of four The transmission system composed of the rod mechanism makes the main knife open first, and then pushes the arc extinguishing knife to open the arc contact, and the compressed air in the cylinder blows out the arc through the nozzle.

According to the voltage used for J, it can be divided into high-voltage load switches and low-voltage load switches.

1. Solid gas-generating high-voltage load switch: use the energy of the breaking arc to make the gas-generating material of the arc chamber produce gas to blow out

The arc has a relatively simple structure and is suitable for products of 35 kV and below.

2. Compressed high-pressure load switch: the compressed air of the piston is used to blow out the arc during the breaking process, and its structure is relatively simple and applicable

For products at 35 kV and below.

3. Compressed air type high-voltage load switch: Use compressed air to blow out the arc, which can interrupt a large current, and its structure is more complex

Miscellaneous, suitable for products of 60 kV and above.

What is the difference in function of circuit breakers, load switches, and isolation switches?

1. Circuit breaker (English name: circuit-breaker, circuit breaker) refers to the ability to close, load and break the current under normal circuit conditions and can close, load and break under abnormal circuit conditions within a specified time Switching device for electric current. Circuit breakers are divided into high-voltage circuit breakers and low-voltage circuit breakers according to their scope of use. The division of high and low voltage boundaries is relatively fuzzy. Generally, those above 3kV are called high-voltage electrical appliances.

Circuit breakers can be used to distribute electrical energy, start asynchronous motors infrequently, and protect power lines and motors. When they have serious overload or short circuit and undervoltage faults, they can automatically cut off the circuit. Their function is equivalent to a fuse switch Combination with overheating relay etc. And after breaking the fault current, there is generally no need to change parts. At present, it has been widely used.

In the generation, transmission and use of electricity, power distribution is an extremely important link. The power distribution system includes transformers and various high and low voltage electrical equipment, and the low voltage circuit breaker is a widely used electrical appliance.

2. The load switch is a switching appliance between the circuit breaker and the isolating switch. It has a simple arc extinguishing device, which can cut off the rated load current and a certain overload current, but cannot cut off the short circuit current.

Generally equipped with a simple arc extinguishing device, but its structure is relatively simple. The picture shows a pressure type high-pressure load switch. Its working process is: when opening, the main shaft rotates clockwise under the action of the opening spring. On the one hand, the piston is moved upward by the crank slider mechanism to compress the gas; In the aspect, through the transmission system composed of two sets of four-linkage mechanisms, the main gate knife is opened first, and then the arc extinguishing blade is pushed to open the arc contact, and the compressed air in the cylinder blows out the arc through the nozzle.

three,

Disconnector (disconnector), that is, in the split position, there is an insulation distance between the contacts that meets the specified requirements and a clear disconnection mark; when in the closed position, it can carry the current under normal circuit conditions and abnormal conditions within the specified time ( For example, short-circuit current switching devices. (IEV441-14-05)

Isolation switch (commonly known as "knife gate") generally refers to a high-voltage isolation switch, that is, an isolation switch with a rated voltage of 1kV or above, usually referred to as an isolation switch, which is the most used electrical appliance among high-voltage switch appliances, which itself The working principle and structure are relatively simple, but due to the large amount of use and high reliability of work, it has a greater impact on the design, establishment and safe operation of substations and power plants. The main feature of the isolating switch is that it has no arc extinguishing ability, and it can only open and close the circuit when there is no load current. Isolation switches are used at all levels of voltage to change circuit connections or isolate lines or equipment from power. It has no current interruption capability and can only be operated by disconnecting the line with other equipment. It is generally equipped with an interlocking device to prevent misoperation when the switch is under load, and sometimes a pin is required to prevent the switch from being opened under the action of a large faulty magnetic force.

The role of Circuit breaker

(1) After opening, establish a reliable insulation gap, and separate the equipment or circuit to be repaired from the power supply by an obvious disconnection point to ensure the safety of the maintenance personnel and equipment.

(2) Change the line according to the operation needs.

(3) It can be used to split and close the small current in the line, such as the charging current of the bushing, busbar, connector, short cable, the capacitive current of the switch voltage equalizing capacitor, the circulating current when the double busbar is replaced, and the excitation of the voltage transformer Current, etc.

(4) According to the specific situation of different structure types, it can be used to divide and close the no-load excitation current of a certain capacity transformer.

More about Indoor and Outdoor application load break switch information see below link:

Outdoor AC high voltage vacuum circuit breaker:https://www.wisdom-pe.com/high-voltage-circuit-breaker/ac-high-voltage-vacuum-circuit-breaker.html

Outdoor AC high voltage vacuum circuit breaker:https://www.wisdom-pe.com/high-voltage-circuit-breaker/high-voltage-vacuum-circuit-breaker.html

Handcart Indoor High Voltage Vacuum Load Switch:https://www.wisdom-pe.com/load-switch/high-voltage-vacuum-load-switch.html

load switch:https://www.wisdom-pe.com/load-switch/wsd-flw34-24-sf6-load-switch.html

AC gapless metal oxide arrester:https://www.wisdom-pe.com/lightning-arrester/ac-gapless-metal-oxide-arrester.html

Outdoor High Voltage Drop Fuse

https://www.wisdom-pe.com/drop-out-fuse/high-voltage-drop-fuse.html

fixed switch cabinet

https://www.wisdom-pe.com/low-voltage-switch-cabinet/ggd-fixed-switch-cabinet.html

AC Gapless MOA

https://www.wisdom-pe.com/lightning-arrester/y5wz-17-45-ac-gapless-moa.html

low-voltage power distribution cabinet

https://www.wisdom-pe.com/low-voltage-switch-cabinet/xl-21-low-voltage-power-distribution-cabinet.html

Wisdom Automatic Equipment Wuxi Co., Ltd.

Wisdom Automatic Equipment Wuxi Co., Ltd. is located in Xishan National Economic Development Zone, Wuxi, an active economic circle in Yangtze River Delta. The company mainly manages 12/24kV intelligent switch cabinet. Outdoor 24kV vacuum circuit breaker; Outdoor 24kV ceramic insulation load switch: Outdoor 27-85kV anti-fouling VI, UV VI high voltage lightning arrester; Automatic mixed flow heating system for high voltage cabinet: Intelligent power transmission and distribution automation system: Box-type transformer substation, capacitor compensation cabinet, distribution box, control box, meter box, etc., and undertake various one-stop services such as preliminary exploration, design, survey, construction, manufacturing, operation and maintenance. It has developed into a professional international engineering company integrating research and development, production, sales, power transmission and debugging.

1. SF6 gas insulation, non -toxic, non -flammable,with excellent arc extinguishingc haracteristics.

2. ln addition standard ceramic bushing, the bushing can be made of silicone rubberlepoxy resin and other materials.

3. Visible disconnection/closure (green disconnection; red dosure).

4. Use the spring energy storage operation mechanism to ensure quick closing and opening operation (less than 100 milliseconds).

5. Remote control can be achieved: with the electronic controller, it can be operated locally or the main console can be operated by FTU interface.